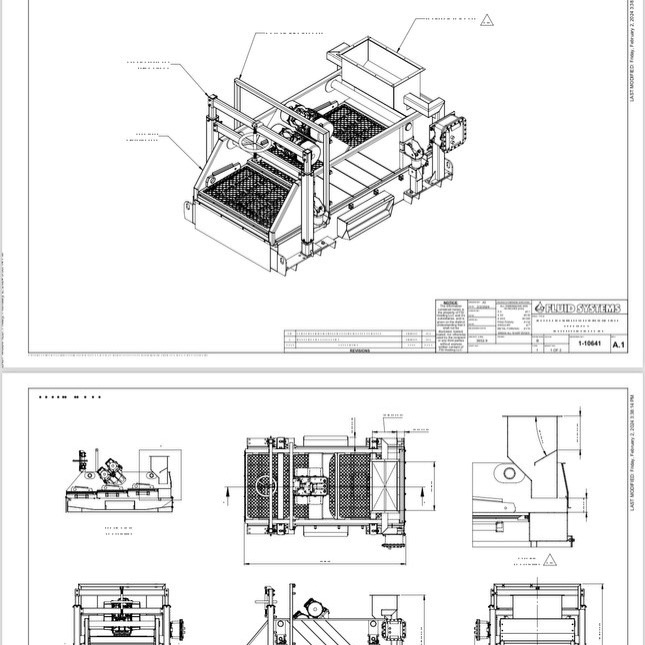

INTRODUCING THE MOST INNOVATIVE SOLIDS CONTROL SYSTEM TO DATE

ACCEE

The ACCEE™ is designed to deliver cost savings, enhance safety, and maximize efficiency, all while minimizing its footprint and environmental impact locally and internationally. With its innovative platform, the ACCEE™ brings a sustainable solution that aligns with the needs of today’s market and the future of global industries.

Advanced

Cyclonic

Chemically

Enhanced

Equipment

The Vital Edge Advantage

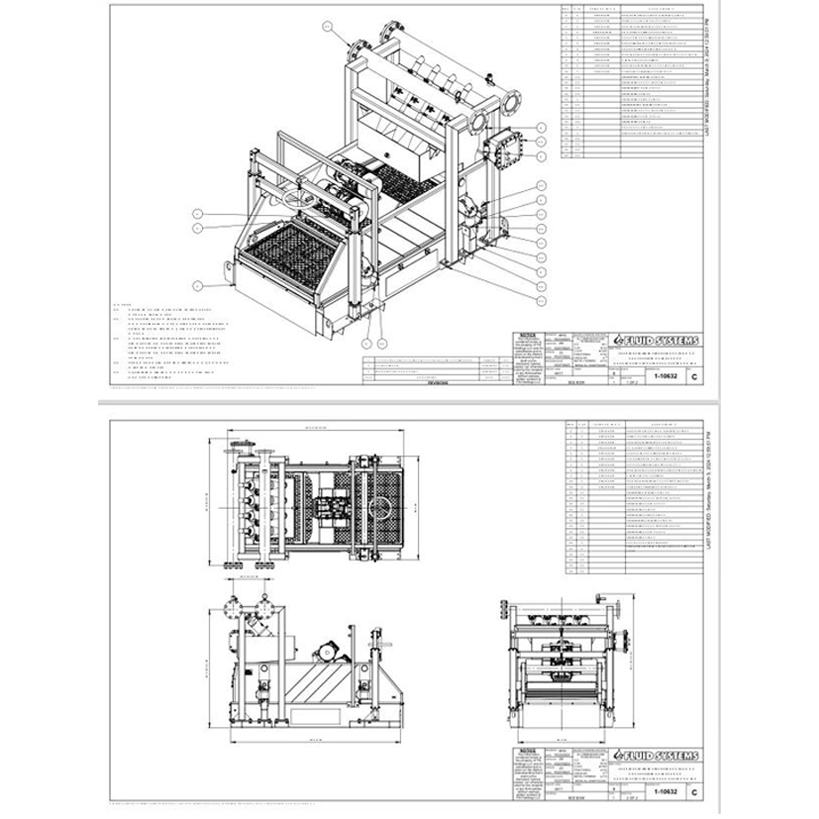

Flare options available via 8’’ discharge pipe, metered and monitored at any desired distance for safe combustible gas discharge.

Flare options available via 8’’ discharge pipe, metered and monitored at any desired distance for safe combustible gas discharge. Each shaker is fed via 2’’ 1502 flowback iron, split over two 6’’ gas busters on our newly adapted degasser.

Each shaker is fed via 2’’ 1502 flowback iron, split over two 6’’ gas busters on our newly adapted degasser. After recent trials, case history and proven Particle Size Analysis , the ACCEE has consistent run time supporting its value. This asset has capabilities of replacing other solids control equipment as a standalone unit. Eliminating costly rig up and rig down charges, with the most efficient fluid through-put. Combination Hi-E shaker and mud cleaner equipment is highly adaptable for all types of fluid systems and can handle on-the-fly changes without complicated modifications to the system

After recent trials, case history and proven Particle Size Analysis , the ACCEE has consistent run time supporting its value. This asset has capabilities of replacing other solids control equipment as a standalone unit. Eliminating costly rig up and rig down charges, with the most efficient fluid through-put. Combination Hi-E shaker and mud cleaner equipment is highly adaptable for all types of fluid systems and can handle on-the-fly changes without complicated modifications to the system